What is Aluminum PCB?

Instead of having a fibreglass or plastic substrate, an aluminium circuit board has a metal substrate. Aluminium PCBs are typically built by an aluminium PCB manufacturer using alloy plates that are a combination of aluminium, magnesium, and silicon (Al-Mg-Si) and have a similar layout to other PCBs. It has a layer or layers of copper, solder mask, and silkscreen layered over it. Aluminium PCB boards are well known for their excellent thermal conductivity and rigidity.

What are the main features of Aluminum PCB?

The Aluminum PCB (metal core PCB or MCPCB) can consist entirely of metal or have a combination of fiberglass and aluminum.

Aluminum PCBs typically are single sided but can be double sided as well.

The aluminum material is less expensive, environmentally friendly (easily recyclable), having better heat transfer capacity, durable and lightweight. They are more cost effective than the copper-based PCBs so it’s a viable alternative for many applications.

Leading aluminum PCB manufacturers and aluminum PCB suppliers cater to industries that require aluminum boards for LED and power-converting electronics due to their excellent thermal conductivity. The main feature of the Aluminum PCB is the intense light produced by LEDs that creates high levels of heat, which aluminum directs away from components thus an aluminum PCB extends the lifespan of an LED device and provides more stability. This is how Aluminum’s high thermal conductivity allows the efficient heat dissipation from electronic components, preventing overheating and extending component lifespan.

The metal core like Aluminum PCB provides rigidity and mechanical strength as compared to the FR4 PCBs, that’s why they can be used in the environment where stress and vibration plays an important role.

What materials are used to build Aluminum PCB?

The Aluminum PCB itself represents the use of metal in the PCB fabrication process. Sometimes they are referred to as MCPCB (Metal Core PCB) and are usually built on an aluminum substrate. Their core uses Aluminum 6061 and 5052 grade materials which have high thermal conductivity, widely used by any reputable aluminum printed circuit boards supplier. Other materials include more specialized and high-quality Bergquist materials.

Below table shows the detailed specifications for the Aluminum material:

| Material | Thermal Conductivity | Coefficient of Thermal Expansion | Density | Modulus of Rigidity | Yield Strength |

|---|---|---|---|---|---|

| Metal /Alloy | (W/mK) | (ppm/K) | (g/cc) | (GPa) | (MPa) |

| Aluminum 5052 | 150 | 25 | 2.7 | 25.9 | 215 |

| Aluminum 6061 | 150 | 25 | 2.7 | 26 | 230 |

Below Table represents the usual thickness of Aluminum PCB Boards. (The highlighted are the standard thickness for the Aluminum PCB)

| Aluminum Thickness | |

|---|---|

| Inches | Millimeters |

| 0.020 | 0.51 |

| 0.032 | 0.81 |

| 0.040 | 1.02 |

| 0.062 | 1.57 |

| 0.080 | 2.03 |

| 0.125 | 3.18 |

| 0.160 | 4.06 |

| 0.190 | 4.83 |

What are the technical aspects, structure and characteristics of Aluminum PCB?

TBecause the Aluminum PCBs are featuring excellent electrical performance, electromagnetic shielding, thermal dissipation capacity, high dielectric strength and bending resistance they are widely used in the industries like Automobiles, power LED lighting, power, television backlight source, computers, air-conditioner etc.

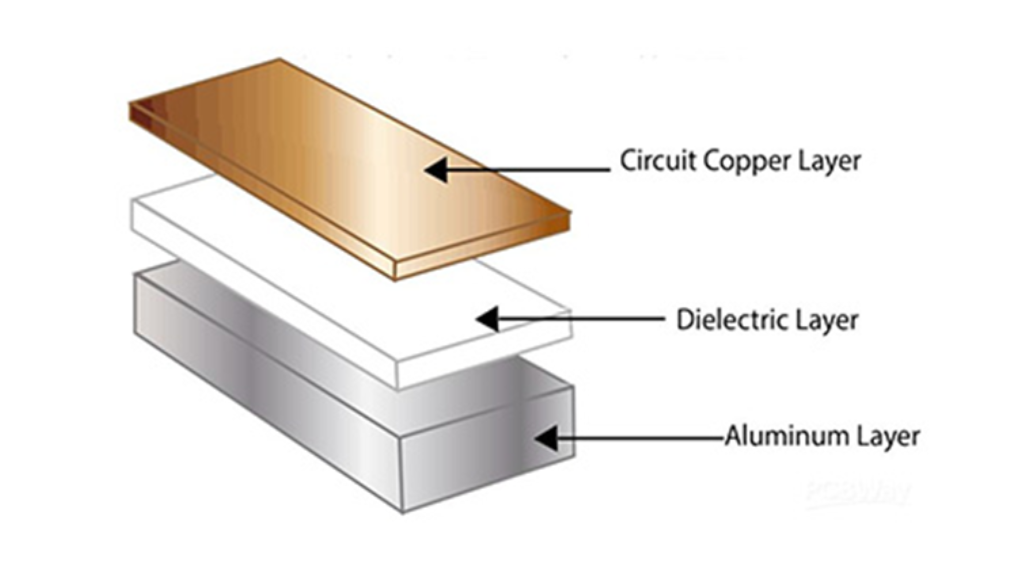

The diagram shows the cross section of the Aluminum PCB structure.

The Circuit layer that is made up of copper foil where we can etch and create the desired circuit patterns.

The Dielectric layer (thermal insulation layer), which is typically made up of ceramic polymer which is placed between copper foil and aluminum base material so to prevent heat being transferred from copper to base material.

The Aluminum layer (Base layer), this core of Aluminum PCB is made up of aluminum alloy which provides excellent thermal conductivity.

There are some other metals present in Aluminum alloy which include magnesium and silicon depending on the properties of the alloy which helps add strength and solderability.

Other layers- as an additional additive, some Aluminum PCB may have an additional protective Aluminum base membrane.

What are the advantages of using Aluminum PCB?

Aluminum PCBs offer a wide range of advantages like:

-

Improved Heat Dissipation:

Aluminum material transfers the heat effectively enables the heat dissipation from heat generating components which ultimately reduces the risk of overheating of the components leading longer life expectancy of the device.

-

Mechanical Strength:

The alloy “Aluminum” is having a good mechanical strength and durability which makes it convenient to use in applications which works in adverse weather conditions and like environments.

-

Electrical Performance:

The Aluminum PCB has low thermal resistance with excellent thermal conductivity, which makes them perform consistently with reliability in high power applications.

-

Lightweight and compactness:

This Metal Core PCBs are to be conveniently able to fit in the small working areas due to their compactness and light in weight. Applications like automobiles can get the best benefit out of this feature.

-

Cost effective:

Because the Aluminum PCBs are simple in design, compact and less expensive than the specialized high-tech PCBs, where liquid cooling or heat sinks are used as a cost-effective thermal management solution. This alloy PCB proves themselves the best.

Choosing a trusted aluminum PCB supplier ensures that your boards meet performance and budget requirements.

What are the different applications of Aluminum PCB?

Because of the Special characteristics of the Aluminum PCBs, they are widely used in several industries like:

High Power LED Lighting

LED generates heat while they are working, in this case efficient heat dissipation is required to perform the device in its normal condition. Aluminum PCBs are the best option for this condition. Applications like street lighting, traffic lights, etc. are the best examples.

Automotive electronics

Light weight, compactness, sturdy, heat dissipation, vibration resistant etc. All these characteristics make Aluminum PCB a favorite in this industry, they can be widely used for ECU (engine control units), LED lights, motor controller, battery management systems etc.

Electronics

The high-power audio equipment, power supply units, thermal printers, etc. uses the Aluminum PCB because of its heat dissipation characteristics and durability with mechanical strength.

Industrial Electronics

Various applications like motor controllers, PLCs (programmable logic card), industrial power delivery units, an automation unit etc. uses the Aluminum PCB because of its unique characteristics.

Telecommunication Industry

The communication devices like routes, antenna, network devices, switches etc. are using the Aluminum PCB for their better performance and longer life.

Power supply and equipment Industry

Power supply units, like SMPS, diodes, etc. uses the Aluminum PCB for the specific characteristics of heat dissipation.

All other industries like Solar Power, Semiconductor devices, Renewable Energy systems, other Consumable devices etc. uses Aluminum PCB in a wide range where durability, heat dissipation, light weight, etc. are the basic requirements.

Why choose Circuitek Solutions Inc. for Aluminum PCB fabrication?

Circuitek Solutions Inc. is a trusted aluminum PCB manufacturer in USA offering proven expertise, quality assurance, competitive pricing, and on-time delivery. With skillful workers and advanced machinery, we manufacture high-quality aluminum printed circuit boards.

We provide several Surface Finishes for the Aluminum PCBs that include Immersion Gold (ENIG), Immersion Silver, Immersion Tin, HASL (Hot Air Solder level), Lead Free HASL, OPS (Organic Solderability Preservative) Hard Gold, ENEPIG (Electroless-Nickel Electroless-Palladium Immersion Gold)

Also take advantage of our ongoing“50% off on tooling cost” offer for your first five orders.