RF/Microwave PCB Manufacturer

What is RF/Microwave PCBs?

A customized PCB that can be used in Wireless communications, Satellite and radar systems, robotics, smartphones, security applications or sensors etc., that are capable of handling high frequency signals (RF and Microwave) with minimum loss of signals and retain maximum level of integrity.

As a trusted RF PCB manufacturer and microwave PCB manufacturer, Circuitek Solutions Inc. specializes in providing advanced solutions for demanding applications.

Key features of RF/Microwave PCBs by microwave PCB manufacturers

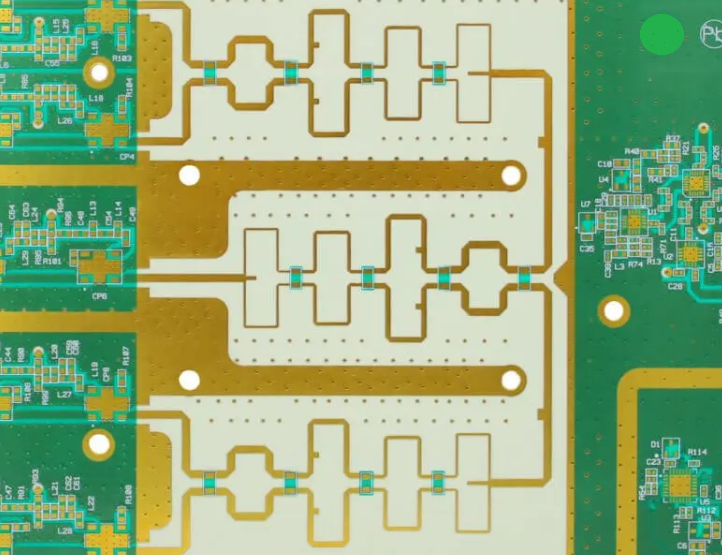

On a PCB, Radio Frequency (RF) operates beyond 100 MHz, are termed as RF PCBs and the Microwave PCB are operates above 2GHz. RF/Microwave PCBs are highly sensitive towards factors such as noise, impedance, electromagnetism, and ESDs (electrostatic discharge).

RF PCBs cover the frequency range used for long-distance broadcasts like FM (87 MHz to 109 MHz), antenna TVs (50 MHz to 890 MHz), and the L band of RADAR, whereas microwave printed circuit boards handle advanced microwave signals ranging from 1 GHz up to 300 GHz.

Materials used in RF/Microwave PCB fabrication

Because RF and Microwave PCB are very sensitive to its operations, a special PCB material that has low dielectric constant, low dissipation factor, and high thermal conductivity like Rogers- RO4000 Series, Isola IS620, Isola Astra and PTFE materials are the best choice. (FR4 material is not recommended for microwave PCB fabrication.)

As an experienced rf microwave pcb board supplier, we ensure only top-grade materials are used for optimal performance.

What are the technical aspects, characteristics and structure of RF/Microwave PCBs?

-

Right Materials:

Material selection is the most important aspect for microwave and RF PCBs. The specialized materials which are designed to carry low dielectric constant, low dissipation and high thermal conductivity as stated in the materials section.

-

Maintaining EMC:

Microwave PCBs are required to maintain EMC (Electromagnetic compatibility) which is critical in microwave PCBs. EMC is maintained mainly by proper shielding and grounding of the PCB, appropriate techniques of routing the traces and EMI filters on the PCB. Failure to maintain EMC results in signal loss and noisy signals on the RF and Microwave PCB.

-

Cost:

Due to the RF and Microwave PCBs are specially designed and using high end materials, with Gold finish, impedances, precise size and structure, they add up the cost than the conventional PCBs.

-

Thermal Management:

Microwave PCBs are sensitive to noise generated in components and traces. The Thermal management in RF and Microwave PCBs is carried out by using a specialized material with high conductivity and low loss tangent factor that can be improved by adding more copper to PCBs.

-

Tolerances and Surface Finish:

The smooth surface finish (Gold preferred), board dimensions and trace tolerances etc. are some of the important aspects that play an important role in maintaining signal integrity on RF and Microwave PCB.

What are the advantages of using RF/Microwave PCBs?

RF and Microwave PCBs are specifically designed boards to use in sensitive devices in a critical environment. They provide a variety of benefits for Megahertz (MHz) to Gigahertz (GHz) frequency ranges for communication signals in everything from smartphones, medical devices to satellite and military radars.

RF and Microwave boards are prepared with specialized high-tech materials to carry high frequency signals with minimal signal loss and maximum signal integrity with the benefits like low loss of signals and keep stable impedance, provides faster data rates with reduced delays, enabling more bandwidth accommodating multi channels.

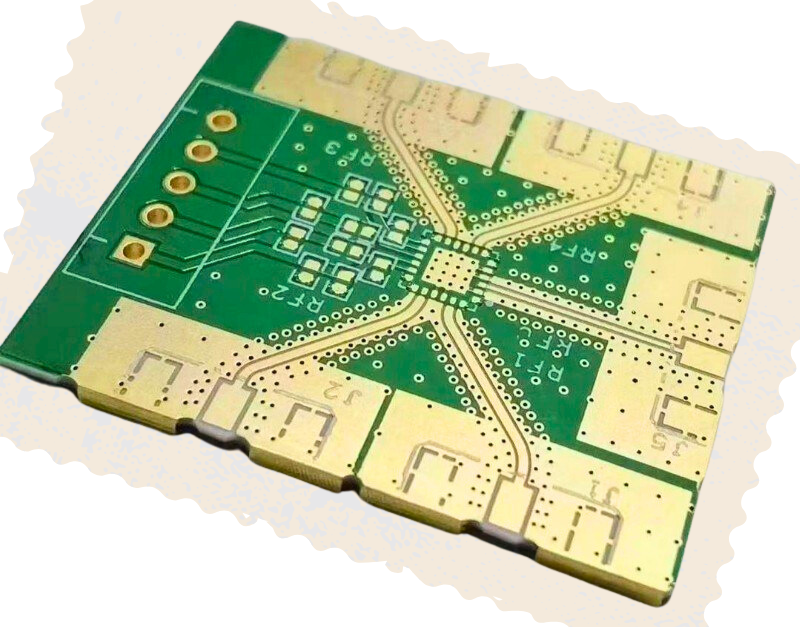

RF and Microwave boards can be built with multilayer structures with specialized materials having low Coefficient of Thermal Expansion (CTE) that facilitate effective placement of fine pitch components also enabling high density packaging that leads to a smaller and compact device.

What are the different applications of RF/Microwave PCBs?

RF/Microwave PCBs are essential for technologies like 5G, Wi-Fi, Bluetooth, and satellite communications, radar systems, cell phones, automotive devices etc. which rely on high-frequency signals for detection and tracking.

RF/Microwave PCBs are used in medical imaging technologies like MRI, CT scan etc. that require high-frequency signals with noise-free operations. For automobile devices they play a vital role in synchronization of data in harsh environments

With the rising need for precision, choosing the right rf pcb manufacturer and microwave pcb manufacturer is crucial for the best application outcomes.

Why choose Circuitek Solutions Inc. for RF/Microwave PCBs fabrication?

The RF and Microwave circuit boards play an irreplaceable role in their designated environments. Their production demands specialized materials like Rogers, PTFE, or hybrids of Rogers + High TG FR-4, and precise impedance calculations — areas where Circuitek Solutions excels.

We pride ourselves on being a reliable rf microwave pcb board supplier and offering top-quality microwave printed circuit boards using our state-of-the-art technology and advanced manufacturing processes.

Also take advantage of our ongoing“50% off on tooling cost” offer for your first five orders.