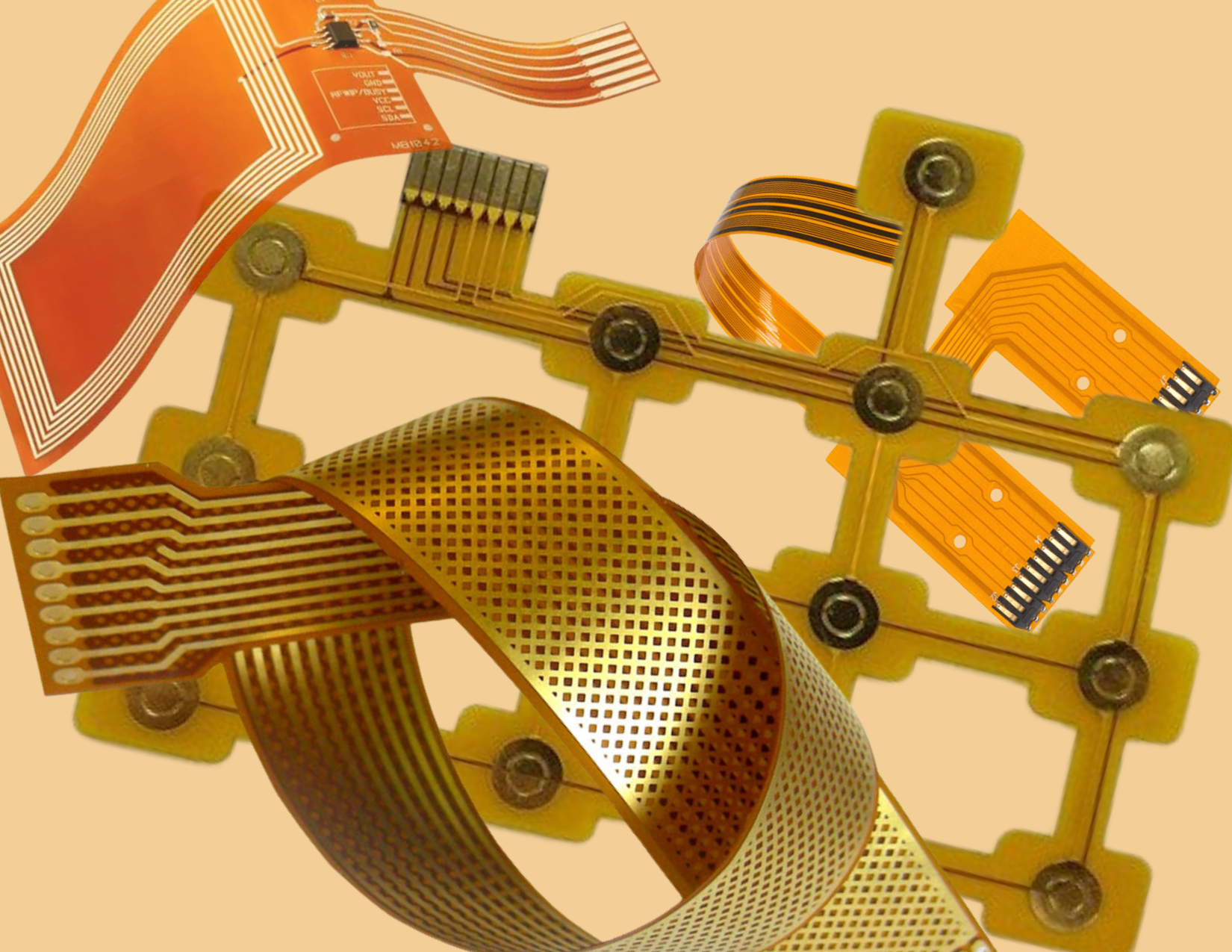

What is Flexible PCB?

The standard Rigid Printed Circuit boards have ruled the electronic industry since a long, in the modern era, there are lots of advanced electronics ruling the market those are compact and lightweight in size and shape accommodating the Flexible PCB inside where the Rigid PCB cannot fit and work. As the name suggests itself, Flexible PCB (Flex Printed Circuit Board) are very flexible in nature yet doing the same extraordinary functions as traditional PCB. They can connect the hard-to-reach parts in the device very easily because of their flexible nature, and that's why choosing the right flexible PCB manufacturer is crucial for delivering precision and quality.

What are the main features of Flexible PCBs?

When you think about Printed Circuit Board, the first thing that pops up in anyone’s mind is a Rigid PCB that is made up of fiberglass-reinforced epoxy material that is mechanically strong and cannot be bent, which provides structure and support to the device. On the other hand, the Flexible Circuit Board is made up of polyimide flex material which does the same functionality with special features like physical flexibility, heat resistance, durability, light weight, and easy to connect components at very congested and hard-to-reach areas inside the devices. The flexible PCBs are thin in size having superior heat dissipation due to better airflow and are suited for extreme temperatures and exposure to gases, acids and oils. They have enhanced reliability due to lack of wiring harness that eliminates chances of wiring errors so that it withstands vibrations and performs consistently in harsh conditions. Usually, they have less assembly cost but are higher in production cost due to special materials and special manufacturing processes.

What materials are used to build Flexible PCBs?

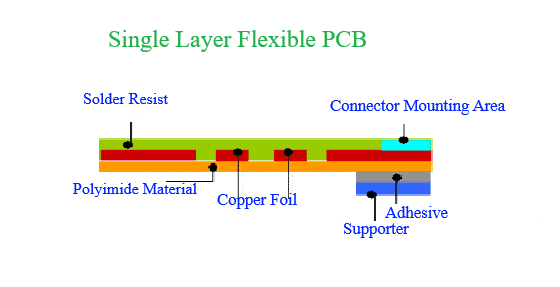

The Flex PCB (Flexible printed circuit board) utilizes a flexible polymer core, usually polyimide (PI) or polyester (PET), Copper foil - which is used for conductive surface with adhesives and coverlays which are used for bonding and insulation.

Let’s understand these materials which are used in flexible PCB manufacturing:

1. Substrate Materials:

-

Polyimide (PI):

PI, is also known as Kapton, which is a common choice for flex PCBs due to its high and low-temperature resistance, adhesion properties and electrical insulation.

-

Polyester (PET):

When the high temperature resistance is not an important factor, the PET material is used as another option, these PET materials are having a good moisture absorption and dimensional stability.

-

Other Polymer materials:

When there is a requirement of exceptional chemical resistance and a high frequency performance the PTFE (Polytetrafluoroethylene) material is used in PCB manufacturing.

2. Conductive Layers:

-

Copper:

Copper is the primary material which is used on the surface of the flex PCB to develop conductive traces and pads.

-

Copper Thickness:

The common thicknesses of copper ranges from 0.5 oz/ft² to 2 oz/ft², depending on the requirement of application - it may vary.

3. Adhesives:

The materials used to bond the copper layers to the substrate are Acrylic or Epoxy-Based Adhesives.

When the application requires high adhesive force, the Modified Epoxy Resin and Acrylic Resin are favorite.

4. Stiffeners:

Stiffeners are made up of polyimide or mostly with rigid FR4 materials, which are added to specific areas of the flexible PCB to provide mechanical support and reinforcement. The purpose of Stiffener is to help prevent bending or flexing in delicate regions on a Flex PCB such as connector areas or mounting points.

5. Surface Finishes:

Common Surface Finishes used for the Flexible PCBs are ENIG (Electroless nickel/Immersion gold), OSP (Organic Solderability Preservative), Immersion Silver, Immersion Tin, and gold are the most common surface finishes used on flex PCBs.

What are the technical aspects, structure and characteristics of Flexible PCBs?

When an application requires space-saving, lightweight materials that perform reliably in harsh environments with heat, vibrations, and extreme temperatures, Flex Circuits are the best fit. Produced by experienced flexible PCB manufacturers in the USA and globally, they are made up of a thin insulating polymer film with conductive circuits, often made from polyimide or polyester materials, and can be folded or bent.

The following technical aspects in its design consideration make them unique:

Flexibility:

Flex Circuits can be bent, folded, and shaped in any way to fit into irregular space, that offers a design freedom.

Dynamic vs. Static Flexion:

Distinguishing between the regular bending and bend-to-install scenarios, as dynamic bending stress can be better managed with single or double layer Flexible Printed Circuit Boards.

Bend Radius:

The radius at which the circuit board can be flexed or bend without compromising its functionality- where the Flexible PCBs came in picture.

Routing:

This parameter in Flex Circuits is the important one which considers minimizing stress points ensuring the proper bend radius of the PCB and is crucial for reliable Performance.

Layer Count:

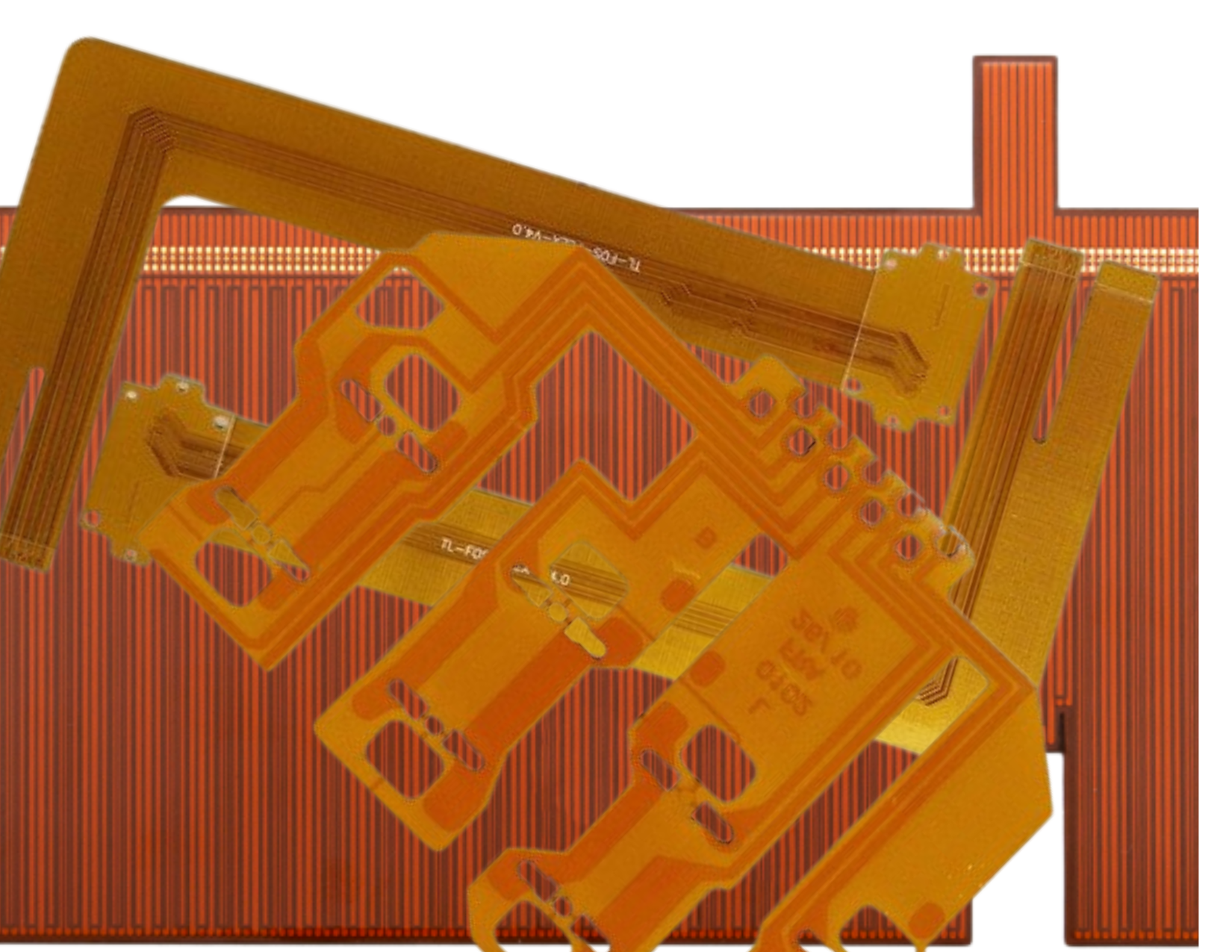

To accommodate the complex and high-density circuit designs a Flex PCBs can be prepared with multiple layers, although they are prepared from single layer, double layer to multi-layer structures.

Controlled Impedance:

The management of electrical characteristics in transmission lines is important for certain high-speed applications, which are carried out with proper impedance control techniques.

EMI Shielding:

To prevent Electromagnetic Interference for many flex PCBs, which helps to absorb radio and other EMI waves. EMI shielding is crucial for ensuring overall performance with reliability.

What is the structure of the Flexible PCB?

Depending upon the requirements of the application, the Flexible PCB can be single sided, double sided or a multilayer PCB.

Single sided flexible PCB:

According to the IPC 6013- Type 1 specifications, the description is: One conductive copper layer which is bonded between two insulating Polyimide layers is called a single sided Flex PCB

Configurations:

- Single-sided access, unsupported fingers

- Standard thicknesses of Flex Core material:1/2 mil to 3 mil in either adhesive or adhesive less construction.

- Standard copper thicknesses: 1/3 oz to 2 oz in finished copper.

- Standard thickness of Coverlay: 1/2 mil to 2 mil polyimides, with 1/2 mil to 2 mil epoxy or acrylic adhesive

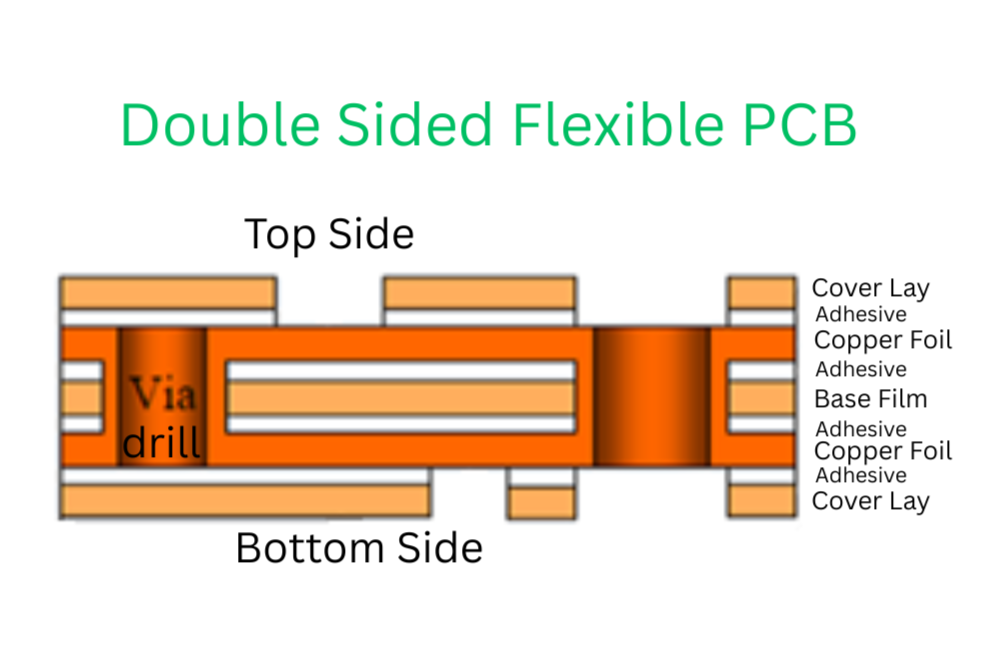

Double sided flexible PCB:

According to the IPC 6013- Type 2 specifications, the description is Two conductive copper layers with an insulating polyimide layer in between, and having an external polyimide insulating layers with Plated through-holes that provide circuit connections between layers.

Configurations:

- Single-sided access and/or two-sided access, PTH technology with castellated holes, via holes, mounting holes etc.

- Standard thicknesses:1/2 mil to 4 mil in either adhesive or adhesive less construction.

- Standard copper thicknesses: 1/3 oz to 2 oz in finished copper thickness.

- Cover lays: Standard thickness: 1/2 mil to 2 mil polyimide with 1/2 mil to 2 mil epoxy or acrylic adhesive

Multi-Layer (4 Layer) Flexible PCB:

According to the IPC 6013 Type 3 specifications, three or more flexible conductive layers with flexible insulating layers between each one and external polyimide insulating layers which are having plated through-holes provide circuit connection between layers are called a Multi-Layer Flexible PCB.

Configurations:

- Single-sided access and/or two-sided access, PTH technology with castellated holes, via holes, mounting holes etc.

- Standard thicknesses :1/2 mil to 4 mil in either adhesive or adhesive less construction

- Standard copper thicknesses: 1/3 oz to 2 oz in finished copper thickness.

- Cover lays: Standard thickness 1/2 mil to 2 mil Polyimide with 1/2 mil to 2 mil epoxy or acrylic adhesive

The Flexible PCBs are characterized by their ability to bend, fold and being flexible, they conform to various shapes, light weight design, and shape saving capabilities making them suitable for applications requiring compact and dynamic electronics in modern applications.

The flexible PCB are thin in size having superior heat dissipation due to better airflow and are suited for extreme temperatures and exposure to gases, acids and oils. They have enhanced reliability due to lack of wiring harness that eliminates chances of wiring errors so that it withstands vibrations and performs consistently in harsh conditions.

What are the advantages of using Flexible PCBs?

The flexible PCBs have some amazing advantages as described below:

-

Reduced Weight:

Because they are very thin in size and there are less components mounted on them, they are almost 90% less in weight than the traditional PCBs

-

Space saving:

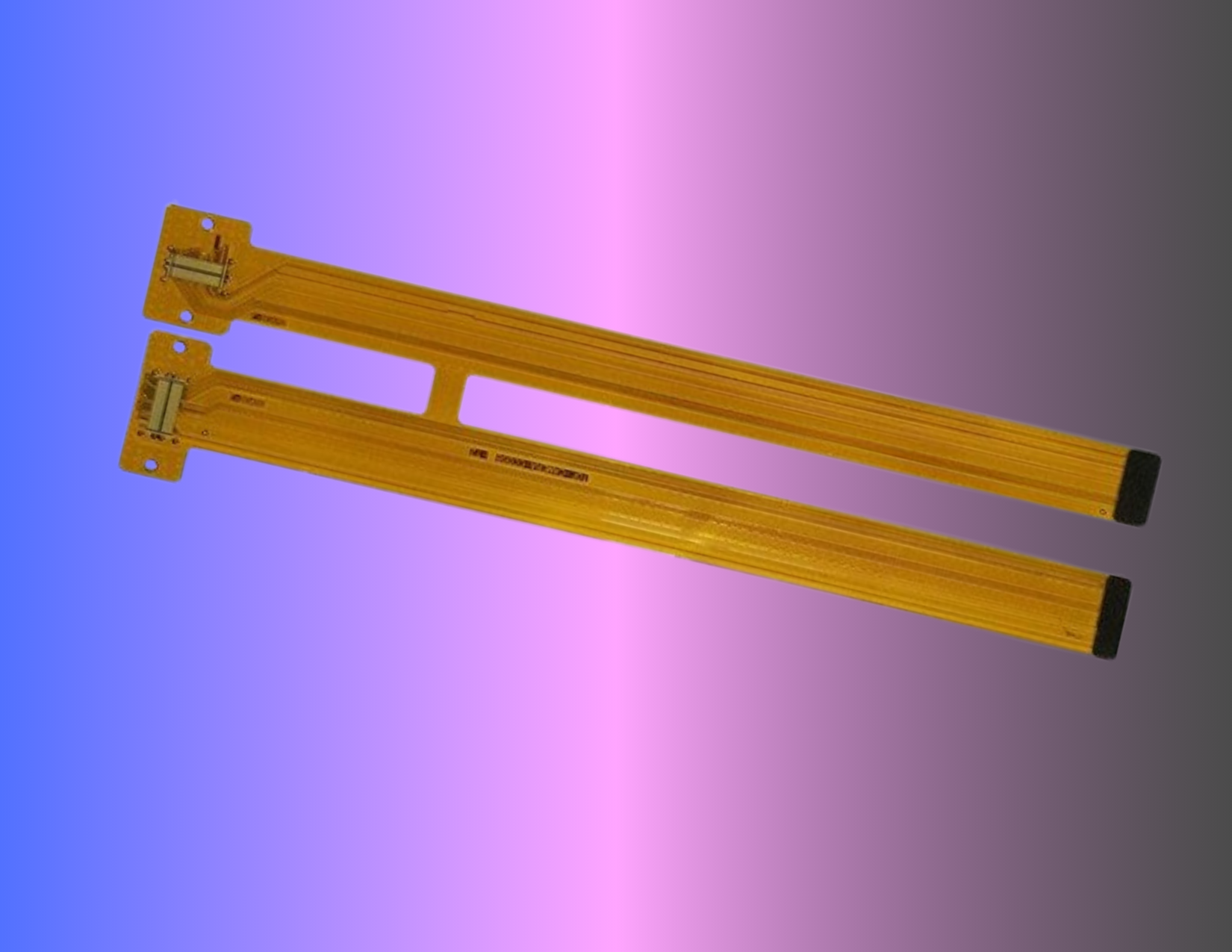

Flexible PCBs, supplied by top flexible PCB suppliers, tend to reach and connect any component even in the most compact devices, helping save space due to their flexible nature.

-

Durability:

The reduced weight and less interconnections in the device allow the Flexible PCBs to be more durable, the flexibility allows them to resist the vibrations making them shock proof. The ability to withstand the mechanical stress improves the reliability and longevity of the Flexible Printed Circuit Board.

-

Enhanced thermal management and signal integrity:

Flexible PCB enhances thermal management by improving the airflow and heat dissipation in the environment they are working in. They are tough in various working conditions and harsh environments with consistent signal integrity and reliability.

-

Versatile Applications:

Because of all the above versatile working nature of the Flex PCB, they are widely used in applications including laptops, mobile phones, wearable devices, medical devices, aviation, aerospace, military robotics applications etc

-

Working error minimization:

Because the Flex PCB has less connectors and reduced hassle in assembly operations and they experience reduce wiring errors that results in working error eliminations.

What are the different applications of Flexible PCB?

Flexible PCBs have ultra-lightweight, flexibility in nature, and the ability to shape in complex ways to connect components. Due to these features, they are increasingly being manufactured by the best flexible circuit board manufacturers for industries including the medical industry (pacemakers, monitoring devices, hearing aids), automotive (airbags, GPS systems, panel displays), consumer electronics (smartphones, laptops, wearable gadgets), aerospace (satellite systems), and more.

Flexible PCBs are also used extensively in other applications and industries like communications, consumer electronic products, military, transportation, robotics, sensor devices etc. where they must perform well in harsh environments with vibrations, heat resistance, physical flexibility, superior heat dissipation, extreme temperatures and exposure to gases, acids, oils etc.

Why choose Circuitek Solutions Inc. for Flexible PCB fabrication?

For the manufacturing of Flexible Printed Circuit Boards, it requires a lot of extra effort and skill. As a trusted flexible PCB manufacturer in USA, Circuitek Solutions Inc. ensures precision, quality, and superior performance for every project.

Design considerations of Flex PCBs

Flexible Circuit Boards have their unique design considerations which are different from the traditional Rigid PCB. Using our expert engineering skills and customized production process we carefully craft all the fabrication strategies to manufacture the Flex PCB that includes a board layer stack up, routing layout and lot of other production procedures.

Right bend radius and bend ratio for flex PCB

Due to all the Flexible PCB designs and applications are different even though they are flexible, we understand the need for their flexibility and strength, we use the right bend and radius with our expertise to manufacture them. This is one of the important aspects of production.

Use of right materials and components

Materials used for fabrication of a flex circuit board define its properties like their dielectric constant, coefficient of thermal expansion, glass transition temperature, fire retarding, and moisture absorption. We understand all the material factors to manufacture the quality Flex PCB.

IPC design, manufacturing, and testing standards

Every of our Printed Circuit Board is manufactured under the strict norms per IPC Standards with expert supervision, that ensures the quality product with proper certifications and standardization.

Quick quotes with competitive prices and turn times

Our prices are competitive without compromising the quality, we always keep the transparency in communication with our customers for accurate and fastest possible turn times without any false predictions.

Let’s connect and we are happy to answer any of your questions and get a non-obligatory quote.

Also take advantage of our ongoing“50% off on tooling cost” offer for your first five orders with your trusted flexible PCB manufacturer!

Interested in what we offer?

Get in touch with us to

find out how

we can help you!

Frequently Asked Questions

| Description of PCB | Tolerance |

|---|---|

| Flexible part thickness | ±50µm |

| Flexible part + Stiffener thickness | ±100µm |