What is a Heavy Copper PCB?

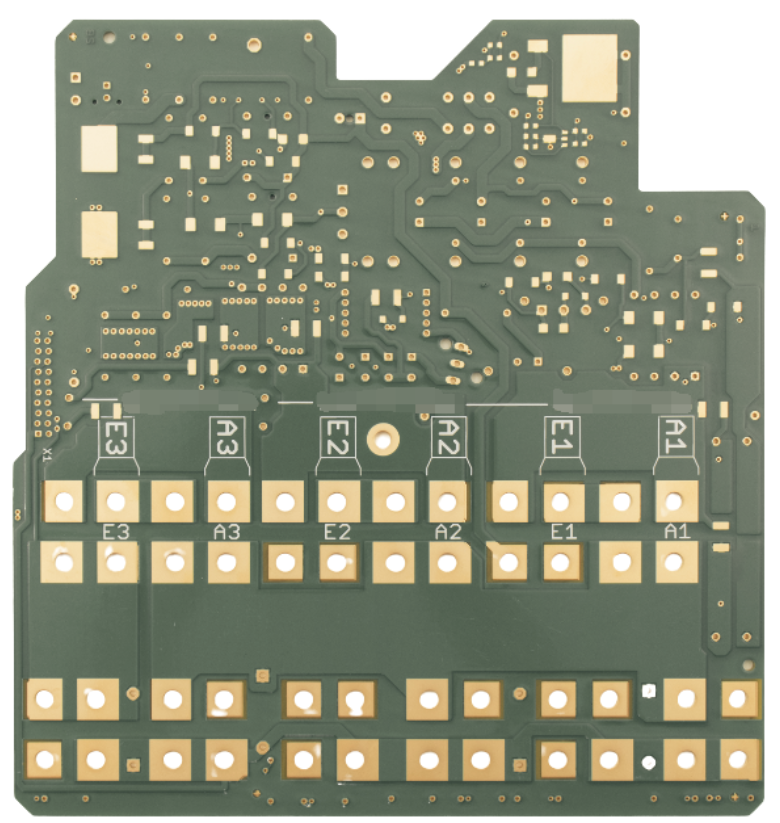

The heavy copper PCBs are used in special applications requiring higher current carrying capacity with variable temperatures to resist for longer periods with better thermal management and enhanced durability, The custom requirements of the copper finish for the Heavy Copper PCB start from 3 Oz. and can go up to 40 oz.

What are the main features of Heavy Copper PCBs?

In this era of rapid development of science and technology, some electronic products demanding high in various aspects like high current and voltage, anti-interference, thermal conductivity, electrical endurance, very extreme use environment, small volume, extremely high reliability etc.The Heavy Copper PCB can fully meet all these requirements. That’s why industries rely on experienced heavy copper PCB suppliers for their critical needs.

What material are used to build Heavy Copper PCBs?

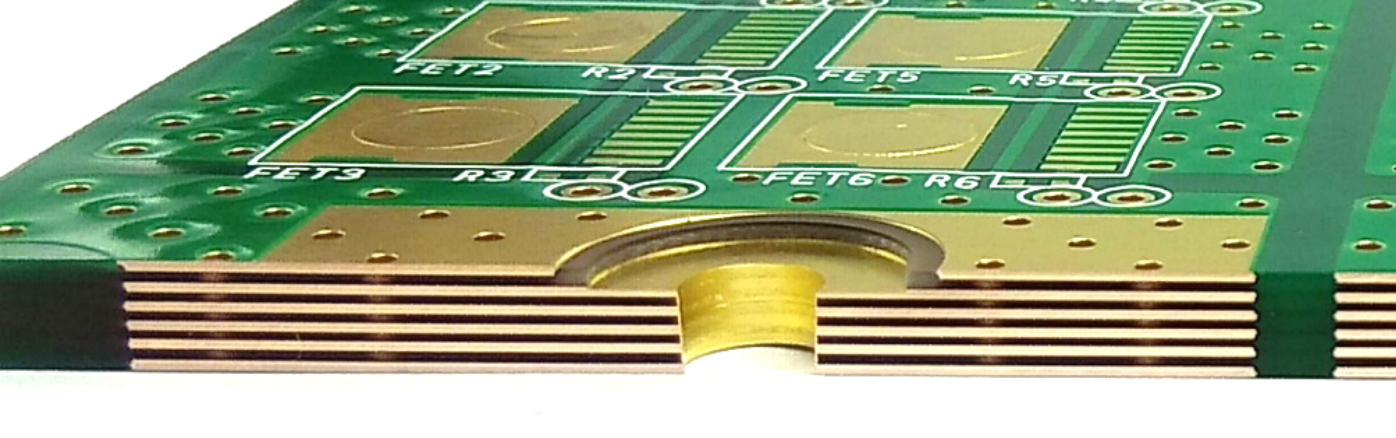

The High TG FR-4 is the mostly used material with different grades to build the heavy copper PCB. If the PCB is multilayer with 3 oz. finished Cu. on outer and inner layers, the construction starts with 2 Oz base copper and electroplating is done to achieve desired copper thickness, same process carried out if there is more copper required and with more than 4 layers, here board construction and board thickness plays a crucial role. Choosing a reliable heavy copper PCB manufacturer in USA ensures the use of high-quality materials and precise manufacturing standards.

What are the technical aspects and characteristics of Heavy Copper PCBs?

They are insensitive to high temperatures or low temperatures with strong corrosion resistance and a much longer life span than the ordinary Printed Circuit Board due to having heavy copper circuits with increased thickness in the plated holes and via sidewalls, this unique design gives the PCB its durable characteristics to performs well in volume simplification withstanding large currents and voltages with extensive heat dissipation rate and are much stronger.

What are the advantages and disadvantages of Heavy Copper PCBs?

Because of the Heavy Copper PCB’s thicker and robust copper content, it performs better in many applications with High reliability, longer life cycle, high current or voltage, high thermal conductivity, and extreme environments.

They have some disadvantages like they cannot be used in PCB with High Density Traces, which are difficult to manufacture and are higher in cost.

What are the different applications of Heavy Copper PCBs.

Heavy Copper PCBs can be widely used in industries like cellular phones, satellite communications, aerospace, network base stations, hybrid integrated circuits, power supply units etc., high power circuits are also used in home appliances, microwave and RF circuits, medical devices etc.

Why choose Circuitek Solutions Inc. for Heavy Copper PCB manufacturing?

Being a leading heavy copper PCB manufacturer in USA and a quality heavy copper PCB supplier, we supply printed circuit boards according to your custom specifications with a range of materials, configurations, and capabilities. We maintain all industry standards so your rigid PCB can operate in numerous environments with consistent durability. Using our expert engineering skills and custom manufacturing processes, we at Circuitek Solutions Inc. specialize in Quick turn, Prototype quantities, Low to high volume production, 2 to 40 layers, Via-in-pad with conductive, non-conductive, or copper plug options, Heavy copper, Control impedance with different finish types including ENIG, ENEPIG, Hard Gold Fingers, wire-bondable electrolytic Gold, immersion Tin, Immersion Silver, HASL, and LF HASL.

Also take advantage of our ongoing“50% off on tooling cost” offer for your first five orders.

Interested in what we offer?

Get in touch with us to

find out how

we can help you!

Frequently Asked Questions

e.g. 1Oz (28.35 grams) of copper is flattened to cover 1 square foot of surface area on a PCB (0.093 square meters), the resulting thickness will be 1.4 mils.